How Often Should Ladders Be Inspected?

October 17, 2024 | Nate Cord

A ladder should be inspected before each use, and a detailed inspection should be carried out every three to six months by a competent person trained in ladder inspection. As a general rule of thumb, ladders used daily should be inspected every three months, ladders used weekly should be inspected every six months, and ladders used less than monthly should be given annual inspections. The Work at Height Regulations (2005) also stipulates that inspections must be performed following any event that may have affected the safe use of the ladder. Note that ladders that are part of a scaffold system still have to be inspected every seven days as part of the scaffold inspection requirements in the UK.

Why We Need Ladder Inspections

Ladders pose serious risks if not maintained or used with care. In the UK, The Health & Safety Executive (HSE) reports that falls from ladders are the main cause of fall-from-height injuries and fatalities, with 50 fatalities in 2023/24 from falls from height. Regular ladder inspections help to:

- Identify wear and tear or damage that could cause the ladder to become unsafe.

- Prevent accidents that could lead to serious injuries or fatalities.

- Ensure compliance with the Work at Height Regulations (2005), which requires all employers to assess risks and conduct ladder safety inspections.

- Extend the lifespan of your ladder by addressing issues early on.

Indeed, some of the main causes of ladder accidents are linked to a lack of risk assessment or inspection.

What Are The Main Causes of Ladder Accidents?

- Failure to carry out a proper risk assessment that determines if a ladder is the right tool for the job. In some cases, a work platform or scaffold tower must be used instead of a ladder, such as if you need to work at height for more than 30 minutes.

- Using a defective ladder, such as one with weakened rungs, broken locks or missing rubber feet, without visual inspection beforehand (where this would be picked up).

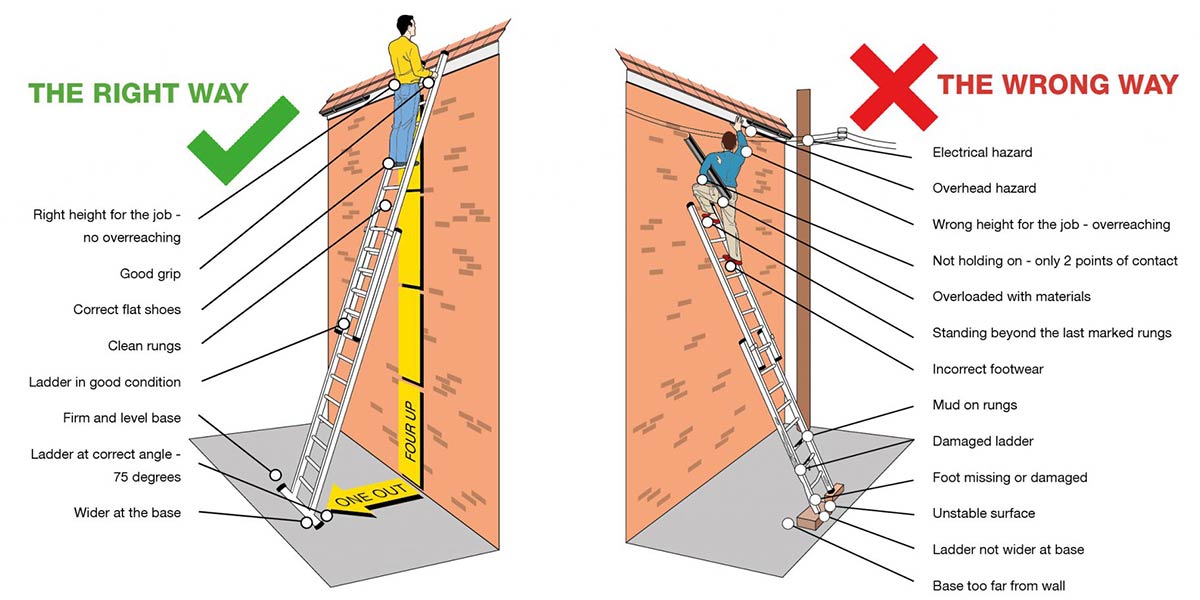

- Incorrect ladder setup, such as placing it on top of an unstable platform, failing to secure the top of an extension ladder, or setting up a ladder at the wrong angle.

- Incorrect ladder use, such as overreaching or overloading the ladder.

How to Inspect a Ladder

A ladder should be inspected before every use to ensure it’s in safe working condition. You should check that your ladder has no visible defects, which will include checking that:

- The rungs are secure, not missing or worn, and free from cracks, dents or bends.

- The feet are intact with good grip, and not damaged or worn.

- The locking mechanisms (on extension and step ladders) are engaging as expected.

- The side rails (or stile) are straight and free from twists, cracks, dents or bends.

- The tie rods are not missing or damaged.

- There are no cracked or damaged welded joints, loose rivets or damaged stays.

If you spot any of the above defects or have any doubts about the ladder’s safety, then do not use it.

Pre-use checks ensure that a ladder is safe to use and this does not need to be recorded. However in addition to daily checks, ladders must undergo a formal inspection every three to six months—or following any event that may have affected the safe use of the ladder—by a trained person, which must be recorded. It’s important to note that different work sites might have different rules – some worksites might require ladders to be inspected and recorded on a daily or weekly basis (and so on).

- Check each part of the ladder, including the rungs, feet and side rails, for cracks, warping, or other signs of structural weakness.

- Check all hardware and fittings are properly and securely attached to the ladder.

- Check that the ladder is clean and free of debris, oil, or other substances that could make it slippery and unsafe.

- Check that the ladder is stable when fully extended or opened.

- Ensure that all locks, hinges, and moving parts operate as expected. Ropes and pulleys should also be in good condition.

- For metal ladders, check signs of rust, particularly around joints, rivets, and welds. You should also check for sharp edges, corners and burrs.

- For wooden ladders, check for moisture damage, chips, splits, cracks and splinters in the rails, holes, or loose parts.

- Ensure that any safety labels, instructions, and load capacity markings are legible.

- If you use a ladder with a platform, you also need to check the platform for defects, such as splits or buckles.

- For self-supporting step ladders, you should also check that the two front legs are of the same length and the two hind legs are of the same length.

- Check that all ladder accessories, such as leg levellers, roof hooks, and shelves, are in good condition.

A record should be kept of each formal inspection, noting any defects or repairs made. Records of these inspections provide a snapshot of the state of the ladders over time.

Ladders that fail inspection should be taken out of service immediately and either repaired by a qualified person or replaced.

A ladder tag can help keep track of inspection dates, or if a ladder is out of use.

Looking for a reliable replacement ladder or other premium access equipment? At Ladders4Sale, we offer a range of ladders, platforms, steps, towers and accessories for all trade and do-it-yourself jobs at unbeatable low prices. Better yet, all of our products come with lifetime support – after your initial purchase, we continue to provide ongoing support and assistance for free. In addition to this, all orders come with free shipping to mainland UK.

Ladder Inspection Checklist

Need a recap or further guidance? Our ladder inspection checklist details what you need to check (pass/fail), with space to make comments and note required actions.

| Inspection Criteria | Check | Pass | Fail | Comments/Actions Required |

|---|---|---|---|---|

| General Condition | ||||

| The ladder is clean and free of debris, oil, etc. | ||||

| Safety labels and markings intact/legible | ||||

| Rungs and Steps | ||||

| All rungs/steps are secure and properly attached | ||||

| Rungs are free from cracks, dents, or damage | ||||

| No visible wear or deformation on rungs | ||||

| For step ladders: Steps a and platforms are flat and secure | ||||

| Side Rails | ||||

| Side rails are straight, with no bends/cracks/dents | ||||

| Side rails are aligned when fully extended | ||||

| Free from rust, corrosion, or splintering | ||||

| Feet and Base | ||||

| Ladder feet are intact, with rubber or non-slip pads | ||||

| Feet are free from cracks or wear | ||||

| The ladder stands securely without wobbling | ||||

| Locks, Hinges, and Braces | ||||

| Locks engage securely on extension ladders | ||||

| Hinges are smooth, and spreaders/braces intact | ||||

| No wear, rust, or damage to locks/hinges | ||||

| Stability | ||||

| Ladder stable when fully opened or extended | ||||

| Extension ladders: Fly section locks firmly | ||||

| Step ladders: Stays fully spread when opened | ||||

| Materials | ||||

| Metal ladders: Free from corrosion/rust | ||||

| Wooden ladders: No splits, cracks, or rot | ||||

| Fibreglass ladders: No cracks, chips, splinters | ||||

| Accessories (if applicable) | ||||

| Stabilisers/hooks are secure and functioning | ||||

| Accessories are free from damage or wear | ||||

| Repairs and Modifications | ||||

| Any repairs done by a qualified person | ||||

| No unauthorised modifications |

If you require additional advice or have a question for our team, don’t hesitate to get in contact with us using this form or via phone at 01639 849847.

Related Products

Be the first to know the latest industry news and offers